The easy to use predictive maintenance software for designing and managing condition-based maintenance plans

Simple and actionable predictive maintenance reporting that helps you optimize your machine reliability and get you the highest return on investment of your plan.

Regardless of the equipment you use or level of your Condition-Based Maintenance plan, Power-MI allows you to manage all your condition monitoring information in one place to create...

Simple and actionable reporting that helps you optimize your machine reliability and get you the highest return on investment of your plan

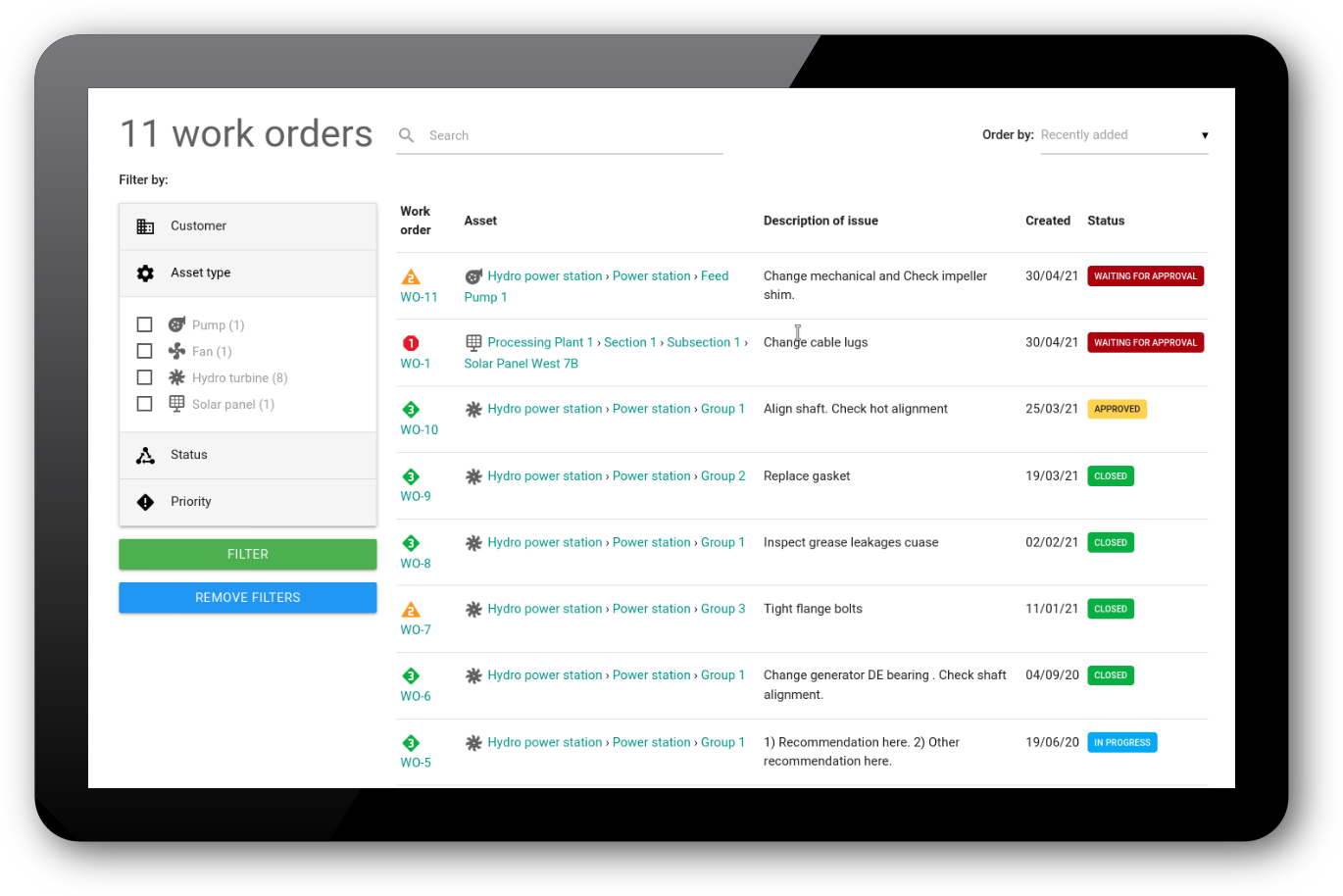

Automate work order creation

No longer will you be forced to waste countless hours capturing the data from your analysts reports and create work orders by hand.

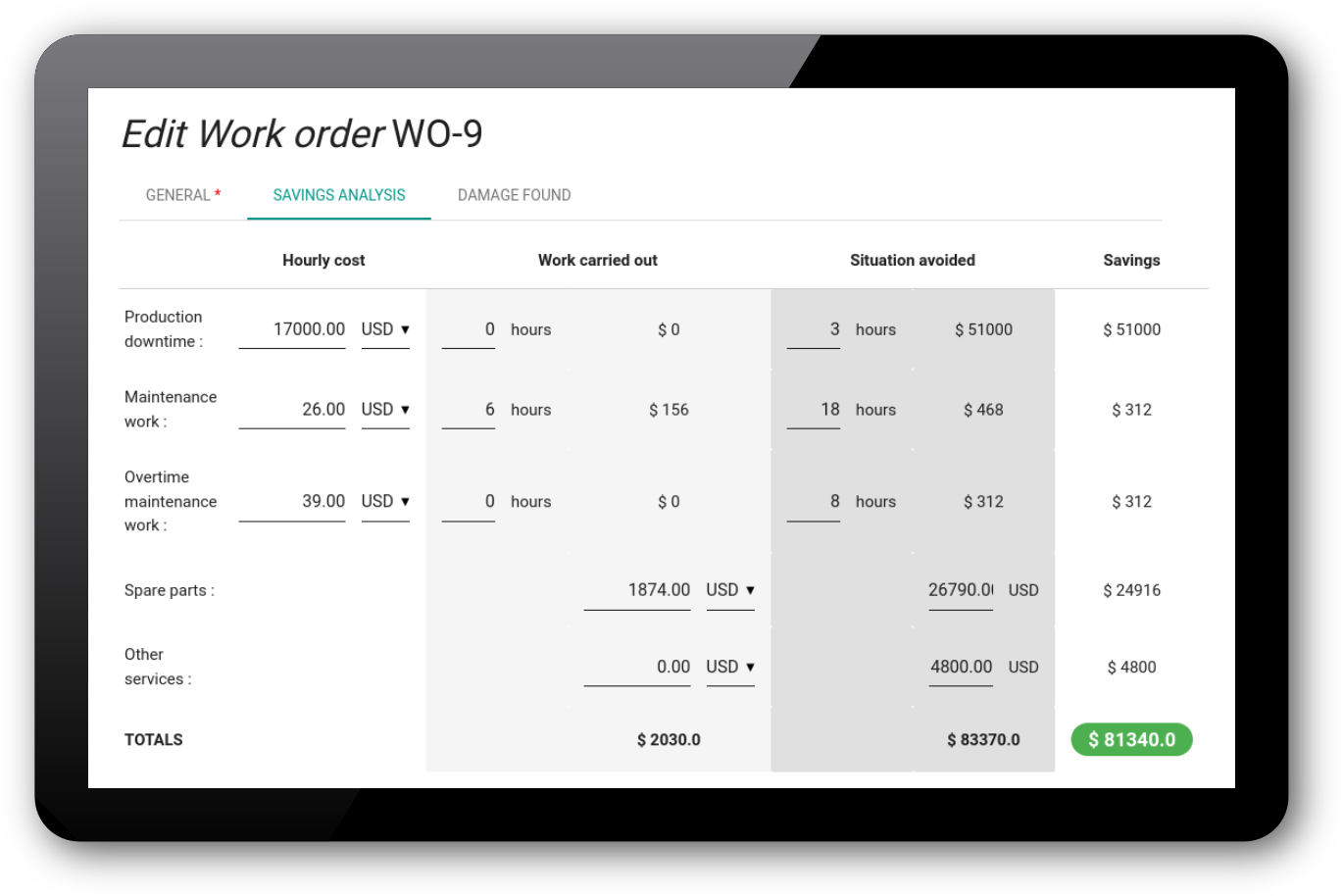

Show the return on investment

You will be able to do root cause analysis and failure mode analysis instantly and finally show the return on investment of all of your actions.

Create your entire maintenance plan

And not only that, but you can create your entire maintenance plan in weeks, not months, using ONE tool. The final result will be even better than what a high cost consultant can deliver.

Ready to take your Condition-Based Maintenance to the next level? It's as simple as...

What can Power-MI help you with?

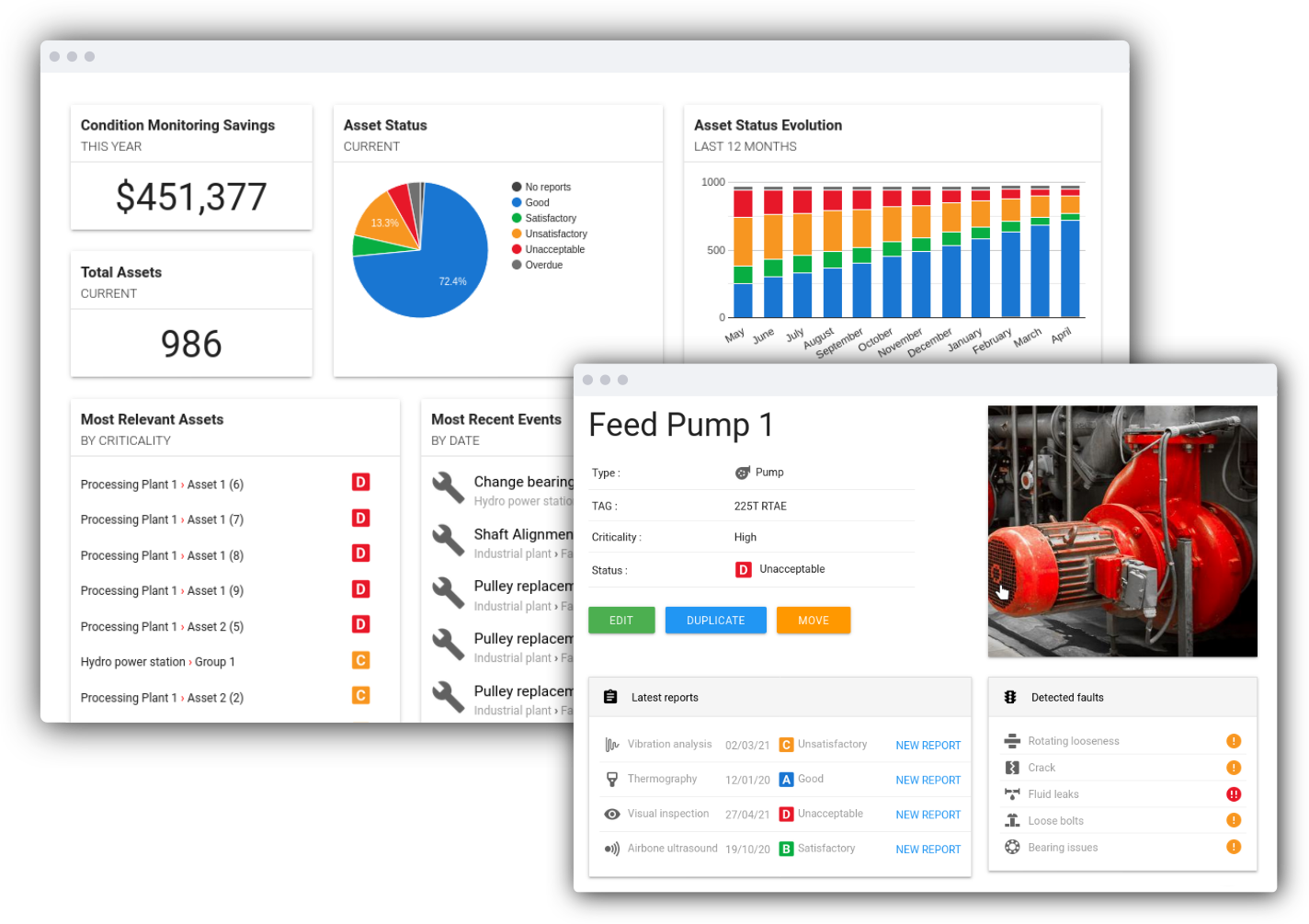

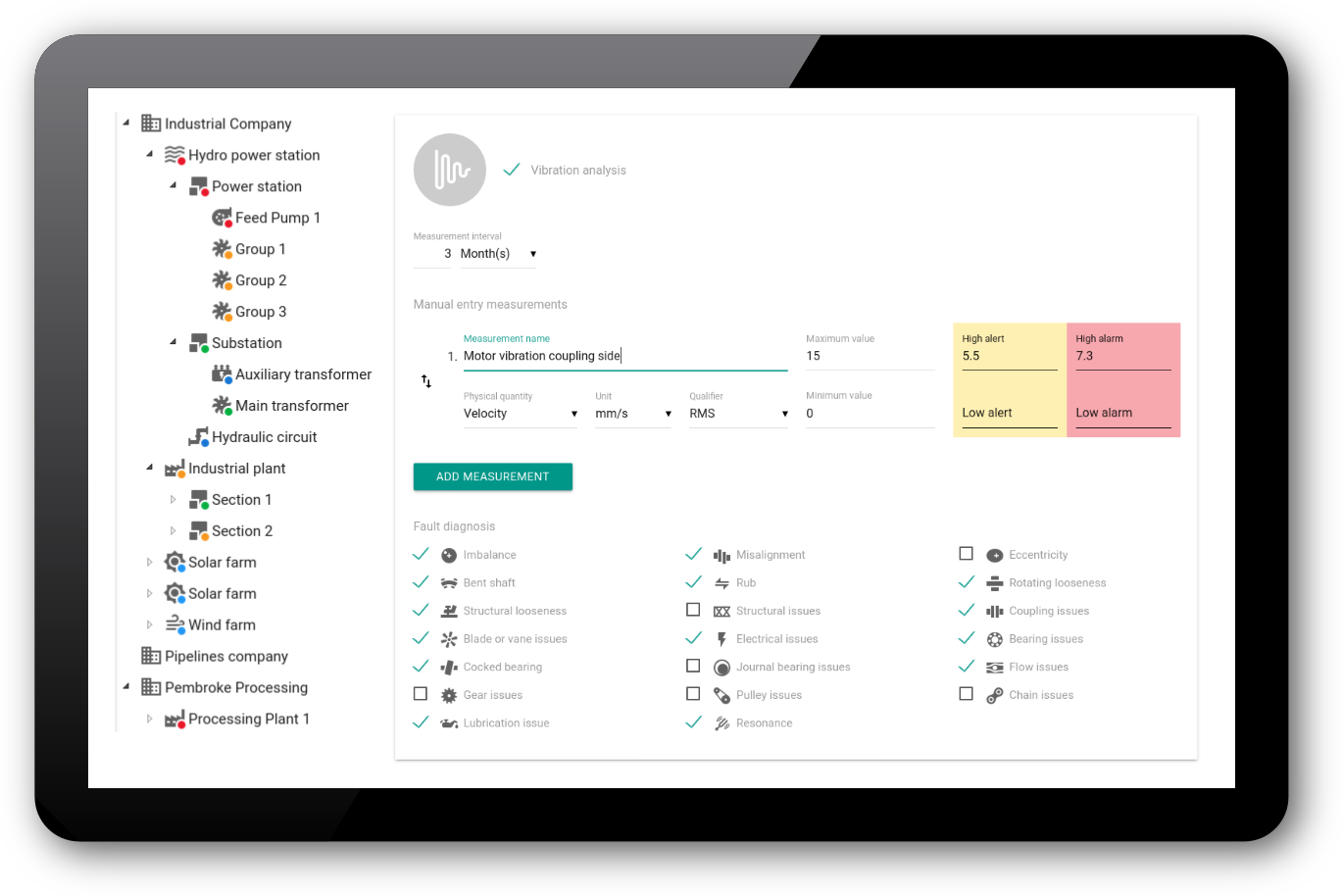

Manage your asset monitoring plan

With Power-MI you can manage your entire inventory, asset hierarchy, automatize your critical failure analysis and easily apply predictive maintenance techniques.

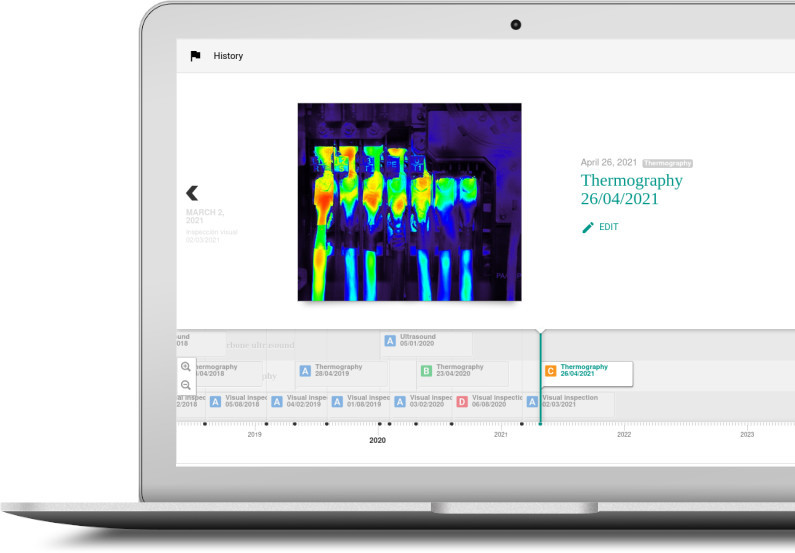

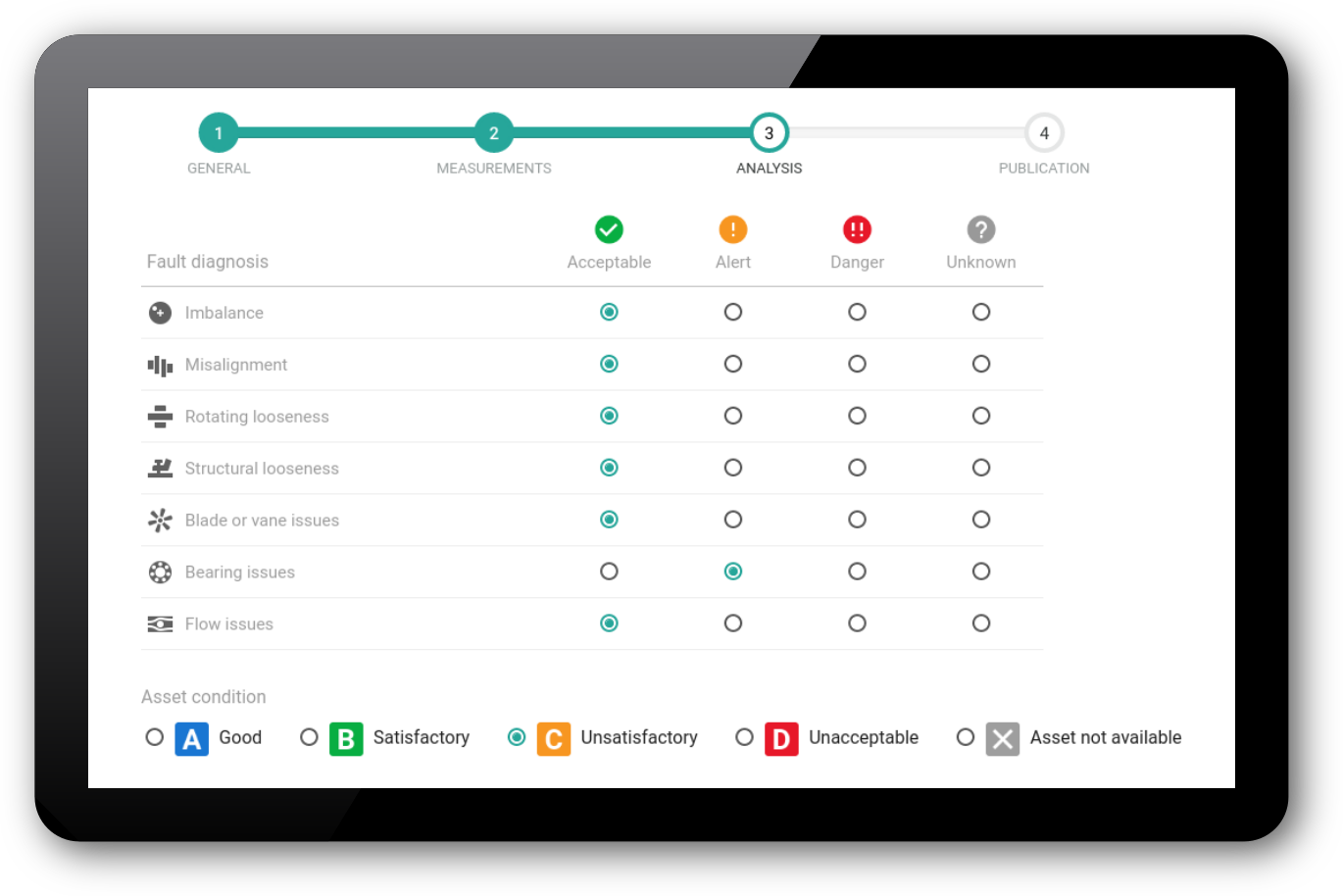

Create fast custom reporting

All of your reports are managed in one single platform regardless of the technology used, equipment brand or analyst.

Automatic work order creation and follow up

Power-MI integrates with your CMMS software enabling you to automate your data management and work-order creation saving you valuable hours every day.

Calculate the condition monitoring savings

With Power-MI you can finally see and communicate the savings of every action and investment you make in your maintenance plan.

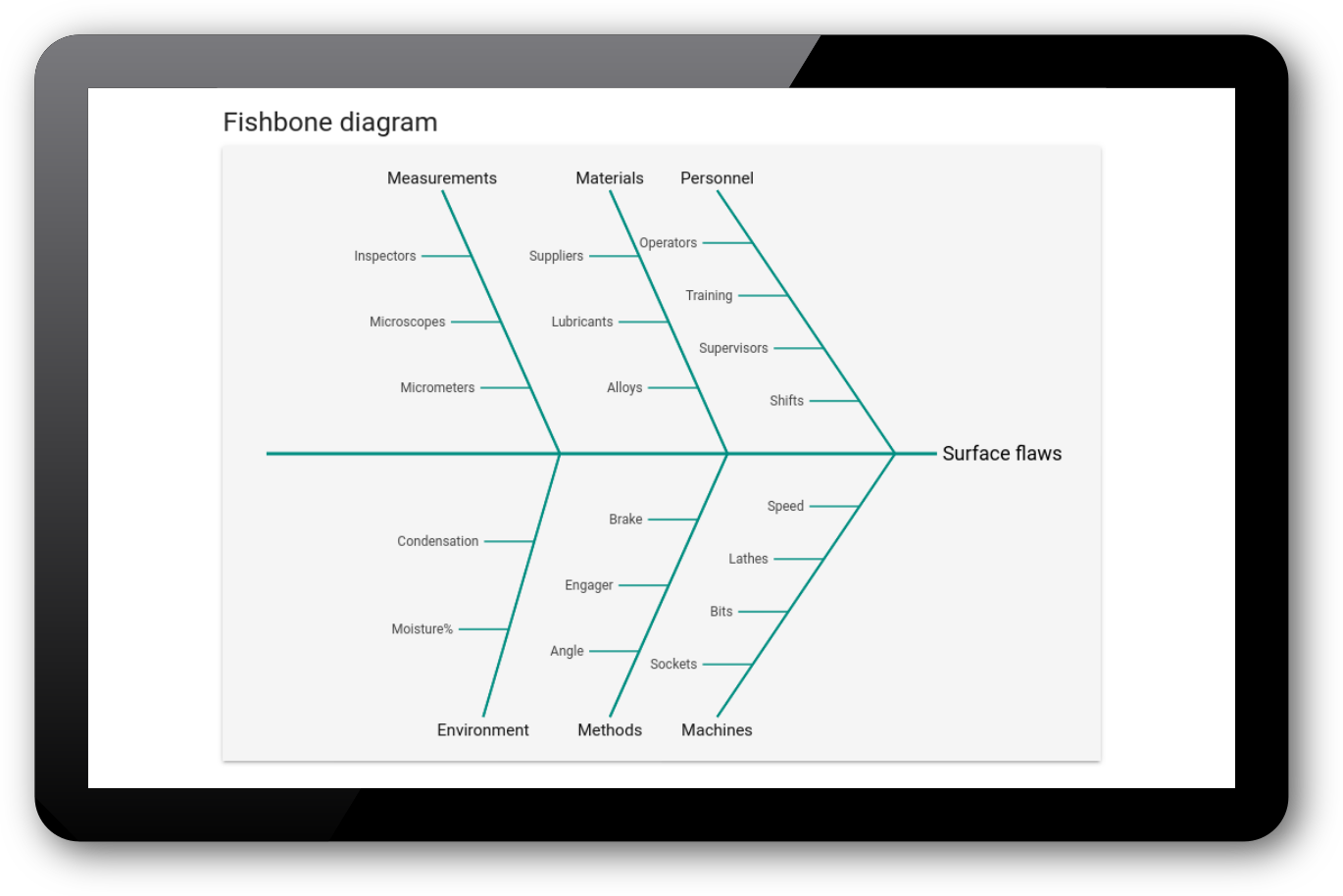

Run root cause analysis

Increase the reliability of your plant with integrated analysis and documentation of: Proactive Maintenance, 5 Whys and Fishbone methodologies.

Power-MI customers

What are Power-MI customers saying

Óscar Domínguez

Technical Director of Diagnosis Predictiva

"I make my reports in less time, free of errors and with a more professional appearance."

Lorenzo Soler

Vibration Analyst Cat II

"Customers see reports always with the same format, and it does not depend on the technician who makes them."

Werner Zelaya

Service Engineer of SIMRO

"It makes the management of my clients and their machines easier; I can see the condition of the machine directly with all its history."

Artur Nenaglyadov

Condition monitor engineer at COSENTINO

"It saves me time when making reports. The format is unified and the tool is simple to use."

Power-MI methodology

Power-MI was created to help you take your plant to the next level. By making it easy to take advantage of all of the predictive maintenance techniques in the Cloud, you will be able to move your maintenance into the Industry 4.0 age using machine learning.

Level 1

Implementation

Assets inventory

Taxonomy and technical documentation.

Criticality analysis

Priority ranking for condition monitoring.

Failure mode analysis

What analysts will diagnose in the field.

Level 2

Management

Unification

All technologies in one format.

Online dashboard

Realtime plant health monitoring for quick decisions.

Calculate the savings

Documented ROI of your CBM.

Level 3

Proactive

Faults statistics

Maintenance Intelligence applied to your asset management.

Root cause analysis

Solve problems by eliminating causes.

Corporate reports

Risk-based CAPEX & OPEX decisions.

Frequently asked questions

-

Can I connect Power-MI with my maintenance software (CMMS)?addremoveYes, Power-MI has an API (Application Programming Interface). If the software used in the plant has an API, it is possible to connect both platforms. The information that is transferred to the CMMS is the work orders generated automatically in Power-MI.

-

Can the reports be downloaded in PDF and have a local backup?addremoveYes, all reports can be downloaded both individually and in summary tables, or as consolidated forms, that is, several reports in a single file can be downloaded and serve as a backup to have locally our information that is in Power-MI.

-

Can I use Power-MI on my cell phone or tablet?addYes, one way is through our application or visual inspection's app where the visual inspections that have been designed in Power-MI are executed because the inspector can go and execute the visual inspections within the app that we have developed. You can also use all the functions linked to Power-MI in either Google Chrome or Safari, depending on the type of tablet or cell phone you have.

-

Is Power-MI only useful if I already have my predictive maintenance implemented?addPower-MI serves both to implement predictive maintenance and if it is already implemented it can be managed in the software. For those who want to implement predictive maintenance, Power-MI offers the tools to do criticality analysis, failure mode analysis and design for each asset its own predictive maintenance plan.

-

Can Power-MI be installed on a local server?addNo, Power-MI is a service that only works in the cloud like any digital platform.

-

How much does Power-MI cost?addThe licenses range from 30 USD per month to 2,000 or 5,000 USD per month depending on what type of license you have and the number of assets we want to manage in Power-MI. All prices can be seen openly on our website, click here to check our pricing schemes.

Ready to take your condition-based maintenance to the next level quicker and easier than ever?

Let us know what type of machinery you want to monitor, what's your current state of condition-based maintenance and what is your overall goal.

Set up a consult call